MicroMill series

The rugged solution for precise milling tasks

MicroMill | Precise & robust CNC routing machine

The MicroMill series was designed to enable precise CNC milling of mild metals, plastics and wood using high speed spindles. The construction of the machine is particularly suitable for shape machining of flat parts and materials with larger dimensions.

Due to the extremely rugged frame, the double-sided driven gantry and the precise linear guideline system, the MicroMill enables excellent results in various shaping jobs. The material can be fixed on the table either with a mechanical clamping system (clamps) or with a vacuum system (MDF pad).

Features

Milling and shaping of fine contours for a variety of materials

• Milling of softer materials like mild metals, plastics, teflon or wood • Suitable for shape machining of flat parts...

Excellent dynamics with positioning speeds of up to 56 m/min.

A rugged machine frame combined with a powerful drive system consisting of digital AC drives, planetary gears and high...

Material fixation options for easy use

The material can either be fixed on the table with mechanical clamps or optionally locked on an MDF pad via a vacuum system...

Vertical design saves workshop space

The vertical routing machine MicroMill-V is available as a particularly space-saving routing solution. The dynamics of the...

Remote Diagnostics

With iMSNC® and numerous remote maintenance modules, MicroStep offers the best foundation for fast and competent help via...

Technical specifications

Dimensions |

|

| Effective length of work area* | 1,500 – 4,500 mm |

| Effective width of work area* | 1,500 – 2,000 mm |

| Effektive height of work area* | 150 mm |

| * Different configurations on request. The net area of the working zone can be operated with all available tools. | |

Tools |

|

| Possible number of tools | 1 |

| Milling spindles | 3.8 – 10 kW, up to 24.000 rpm * |

| Conical holder type | ISO30 * |

|

*other spindles and conical holder types possible upon request |

|

Precision |

|

| Positioning speed | max. 56 m/min. |

| Bidirectional repeatability | according to DIN 28206 / 0.03 mm/m |

| X, Y axis | linear guides, driven on both sides and helical toothed racks |

| Z axis | high-revolution spindle |

| Gantry type | massive steel gantry |

Control & software |

|

| Control | iMSNC® |

| Main control panel | ergonomic 17" touchscreen control panel |

| Operating system | Windows 10™ 64-bit PRO |

| Additional control panels |

1 control panel on gantry, optional an additional control panel on gantry or additional control panel in a rotary holder at the end of table |

| All specifications subject to change | |

Software

Control

MSF iMSNC® machine control

Intelligent solution for cross-technology work with the laser cutting system

The system consists of a stand-alone control console with a 24" TFT touchscreen monitor. If cameras are implemented in the interior, the existing touchscreen can be supplemented with an additional screen for displaying live images. In order to achieve maximum utilization and flexibility of our machines, the ergonomic control console offers you the possibility – parallel to running cutting processes – to nest new cutting programs and generate additional CNC codes. As the iMSNC® control system and all CAM software solutions come from our company, the software with its versatile modules can be individually customized for your production. Parameter databases for individual technologies enable consistently high quality under various circumstances. iMSNC® comes with multiple efficient evaluation tools for production process optimization. These provide you with the much-needed overview of current cutting orders, cutting times, cost calculations and machine utilization in day-to-day production.

Overview of important performance data:

- MMi console and 24’’ touchscreen

- Display of existing cameras in the interior via additional screen (optional)

- Efficient management of tool data

- Very short programming times

- Fast data transfer

- Flexible and easy to use

- Advanced cutting simulation for more work safety

- Convenient contextual help via pop-up bubbles

Media

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

MSE SmartFL

MSE SmartFL

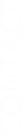

MSE TubeFL

MSE TubeFL

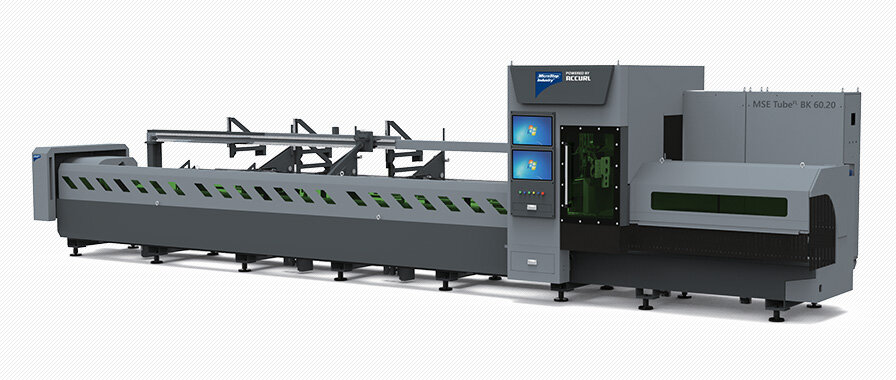

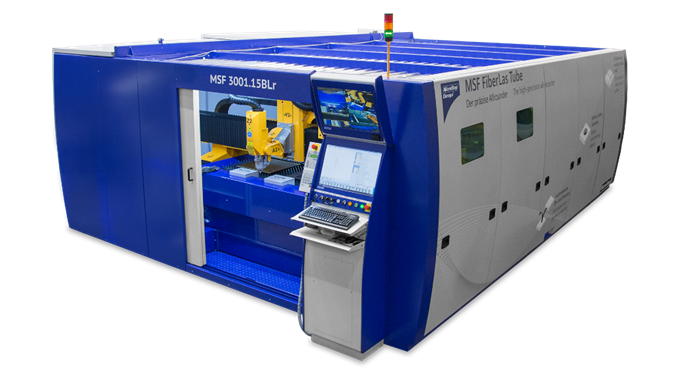

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

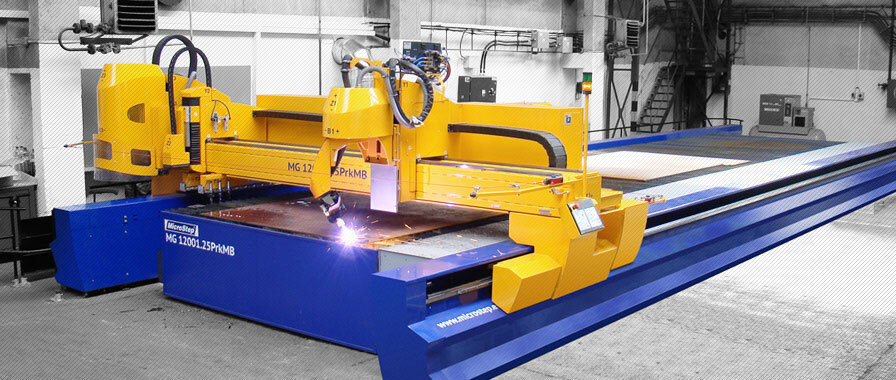

MG

MG

DRM

DRM

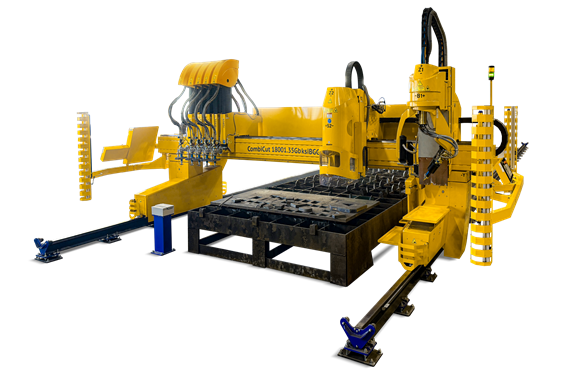

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

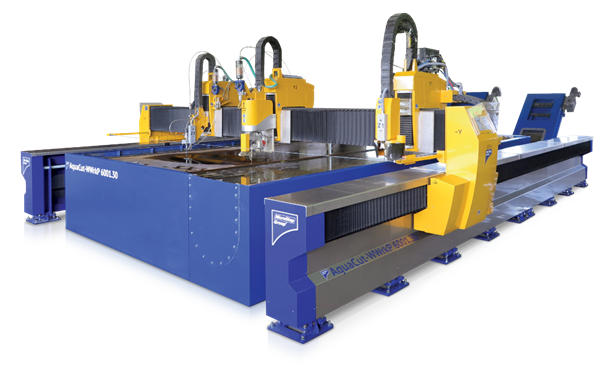

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

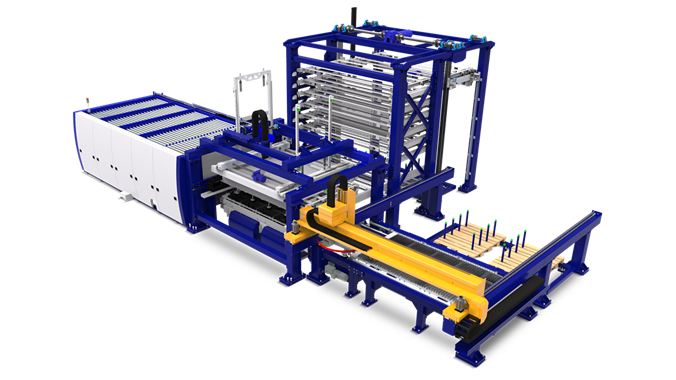

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization