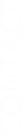

With MicroStep systems you are already well prepared today for the networked production of the future.

MicroStep: Pionier of digitalization

As a manufacturer of industrial cutting systems, we have always made consistent use of the opportunities offered by progressive digitalization: We recognized early on that the new possibilities allow our customers to produce even more efficiently and competitively as a result. Against this background, we have developed numerous technologies that would be inconceivable without digital processing of data: For example, our automated calibration system ACTG® , which ensures maximum, process-reliable quality in bevel cutting. Technologies such as these are one of the foundations of the great success story of our group of companies.

In addition, MicroStep has already implemented automation solutions worldwide, some of them highly complex, for a wide range of requirements. Therefore, we know that the great potentials of digitalization are not only lifted with isolated solutions, but especially in the context of a networked production. We understand that digitalization can unfold a revolutionary optimization of industrial production, especially if it is thought of holistically within the framework of a Smart Factory.

It's up to us to make something of it!

"We have also digitized almost all internal processes at MicroStep Europa GmbH - this saves time that would otherwise have to be invested in bureaucratic tasks. Time that we can use instead for dialog with our customers and interested parties. And at product level, too, we have already significantly expanded customer benefits through digital services and functions. We have realized this: Digitalization creates opportunities, but it's up to us to make something of them!"

Igor Mikulina

Managing Director MicroStep Europa GmbH

Chairman Industry Business Network 4.0 e.V.

MicroStep Smart Features: Ready for the Smart Factory!

With MicroStep machines you are already well prepared today for the future of the Smart Factory:

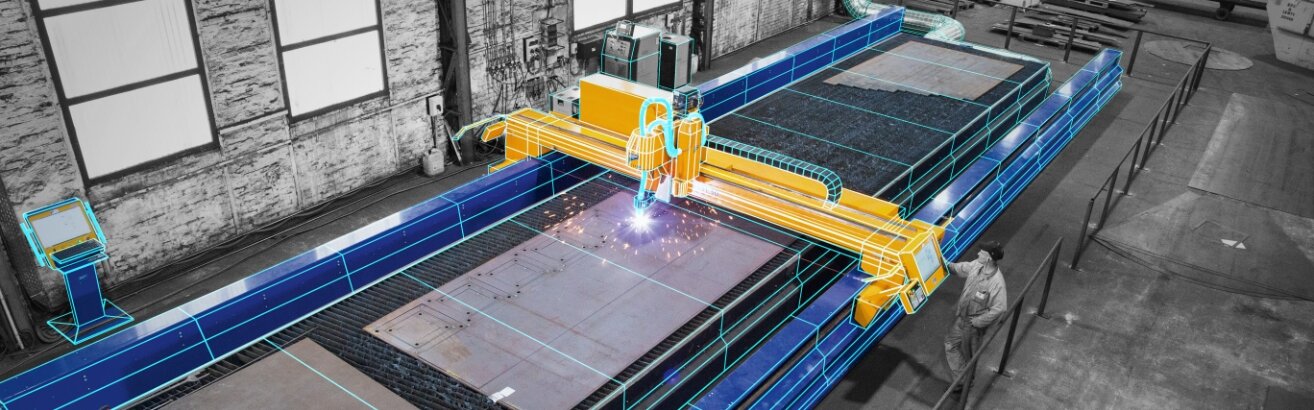

MicroStep offers the complete package: Optimize your production planning and ensure that your components can be produced at competitive costs!

- 2D / 3D CAM systems for the creation of NC programs for the multi-functional processing of sheet metal, pipes, profiles and domes

- Simulation of even complex NC programs based on the actual configuration of the cutting machine

- Definition of optimization priorities: waste minimization, parts position on semi-finished products, processing time, etc.

Increase the efficiency of your production with the advanced solutions from MicroStep!

- Intelligent production management software including supply chain management

- Production quality assurance based on monitoring parameters affecting the cutting results (e.g. automatic self-calibration of cutting tools)

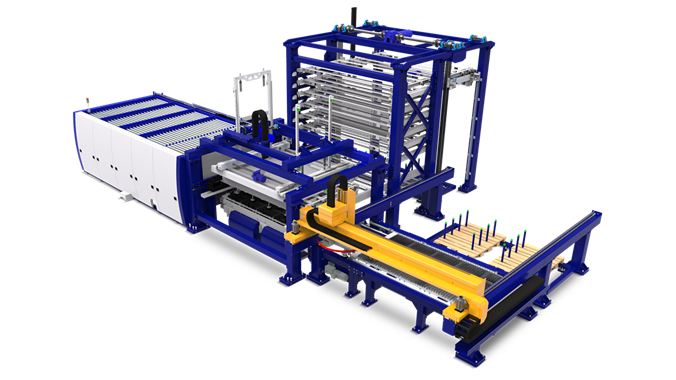

- Fully or partially automated material handling from and to the system

- Expert systems support the configuration of cutting tools and wear part management

- Intelligent work zone management

- Processing of NC programs from different sources

Network your MicroStep machine via standardized protocols and interfaces!

- OPC UA

- MQTT

- Connection to ERP / MES systems

- Networking with other machines and systems (e.g. power sources, filter sources, storage systems, handling systems)

Have a permanent overview of your MicroStep machine!

- Visualization of the current status and history of all relevant machine parameters (e.g. machine condition, wear of wearing parts etc.)

- Efficient management of cutting plans

- Output of all parameters used for cutting, e.g. for documentation obligations within the scope of legal production standards

- Evaluation of your company and order relevant key figures (e.g. cutting times, cutting costs, material consumption etc.)

- All information available on the intranet as well as via secure internet connection

Digital services support the professional maintenance of your MicroStep machine!

- Consistent monitoring of service intervals and running times helps you to plan maintenance work and minimizes the risk of unplanned machine downtimes

- MicroStep RemoteDiagnostics®: For fast and uncomplicated fault analysis via the internet if required.

- Through the use of Augmented Reality (AR), our technicians on site are directly networked with specialized application experts if necessary

MSE SmartFL

MSE SmartFL

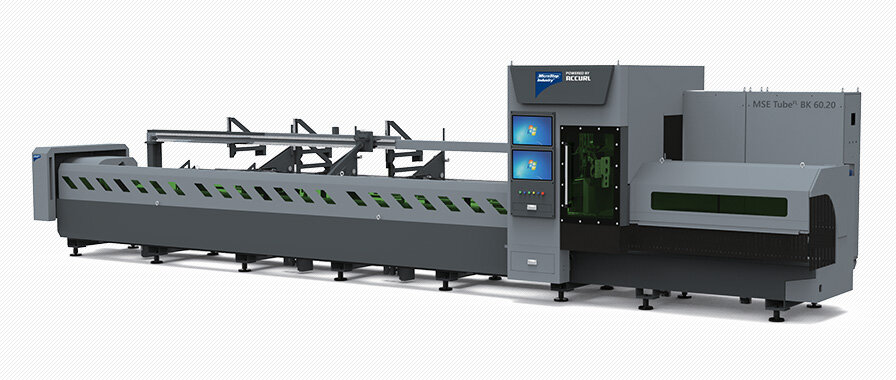

MSE TubeFL

MSE TubeFL

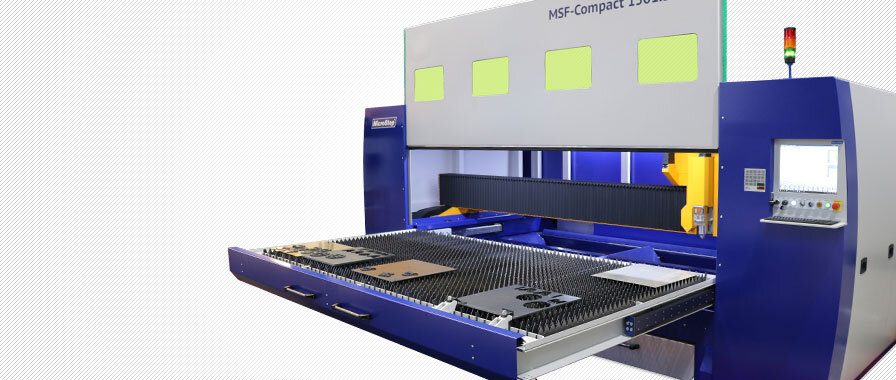

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

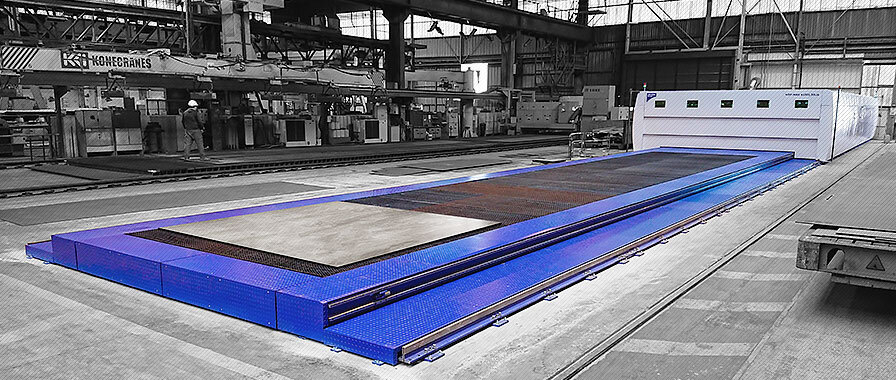

MSF Max

MSF Max

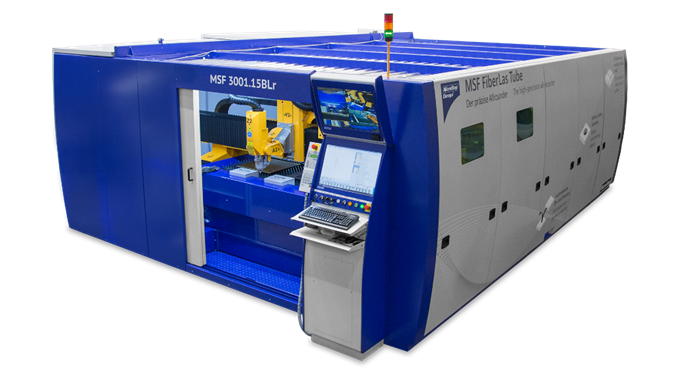

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

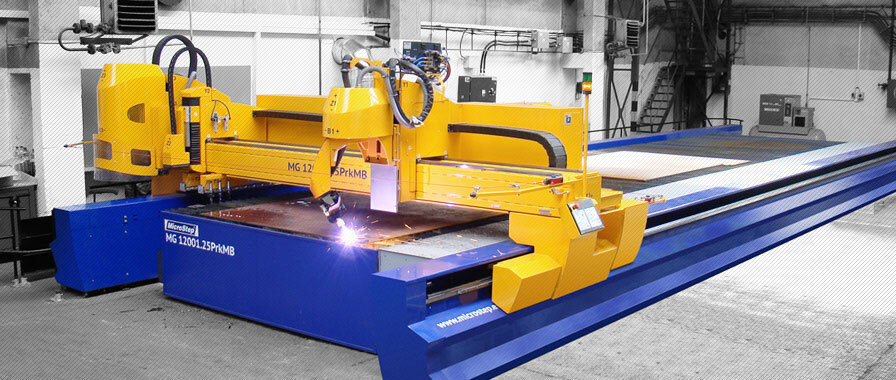

MG

MG

DRM

DRM

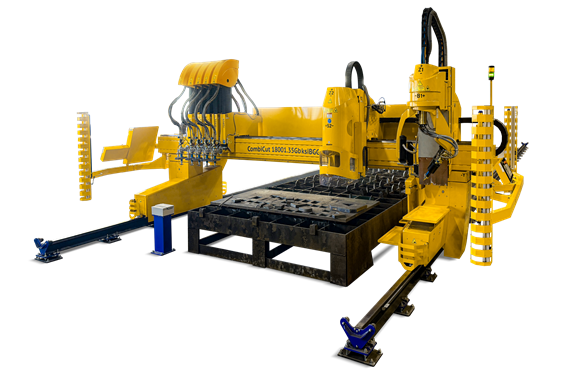

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

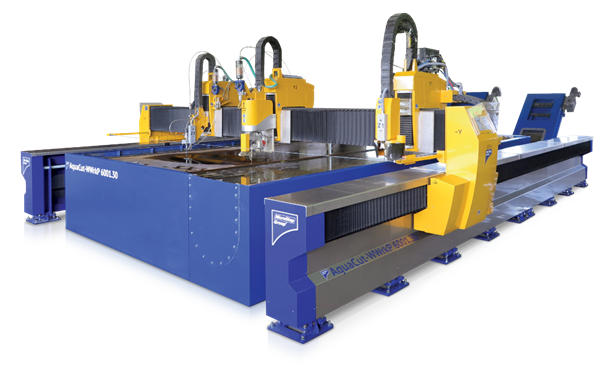

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization