MSE TubeFL

High-precision and fast solution for 2D and 3D processing

of tubes, profiles and beams

The MSE TubeFL | Laser cutting of tubes, profiles and beams

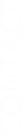

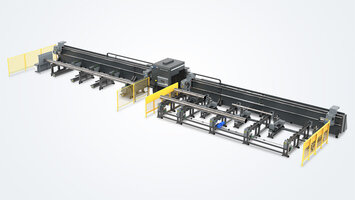

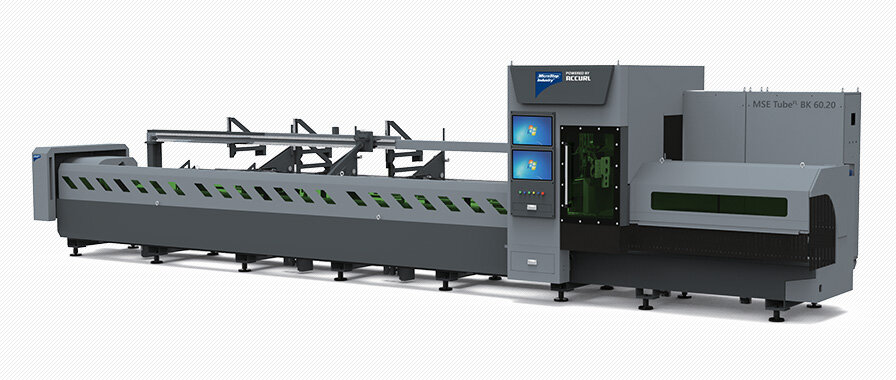

The MSE TubeFL series was developed for the reliable, high-precision and fast 2D and 3D processing of tubes, profiles and beams. The fiber laser cutting system from MicroStep Europa and our technology partner ACCURL enables the precise processing of tubes up to 12 meters in length and 510 mm in diameter as well as profile cutting up to a length of 12 meters and an edge length of up to 510 mm. Depending on the version, the system has an extremely high degree of automation. The loading and unloading of cut parts can also be almost completely automated.

The highly dynamic machine is perfectly suited to the production of high-precision parts at high cutting speeds – allowing the finest contours and openings as well as exact bevel cuts to be realized. Square tubes, round tubes, elliptical tubes, flat tubes and triangular geometries as well as I-beams and other material shapes can be clamped and processed easily. The fiber laser system, which offers a choice of laser sources with an output of up to 12 kW, has amazingly low maintenance and operating costs.

Features

A highly efficient solution that guarantees maximum productivity

The MSE TubeFL is a compact and efficient solution for tube, profile and beam cutting with numerous advanced technologies for...

Tube, square and beam processing with a high degree of automation

Cutting of pipes (up to 510 mm Ø and 12 meters long) and square profiles (up to 510 x 510 mm edge length and 12 meters total...

Robust mechanical engineering for excellent process reliability

Technology partner Accurl has developed robust, pneumatically operated chucks for the MSE TubeFL series. These can precisely...

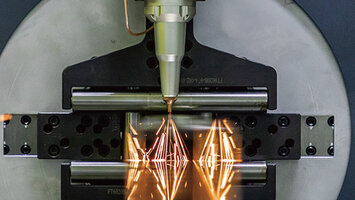

Laser rotator for bevel cuts up to 45°

Depending on the version, the MSE TubeFL can be equipped with a laser rotator for bevel cuts from -45° to +45°. In...

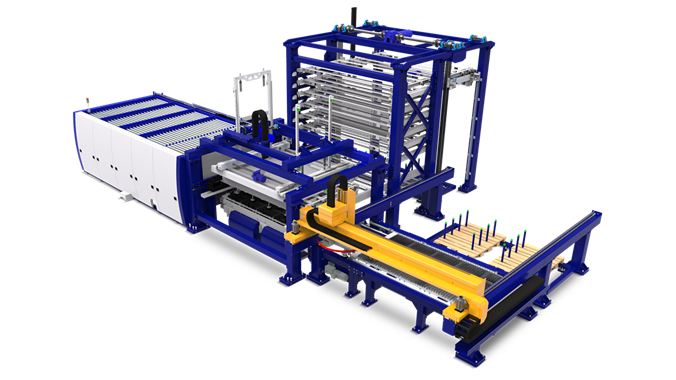

Maximum automation capability

The optional ATL loading system for the MSE TubeFL series works fully automatically and requires no mechanical intervention...

Special design for particularly large pipes, profiles and beams

The series is available in a special version in which an automated loading and unloading system for particularly large tubes...

High efficiency in spite of strong performance

Highly attractive pricing with comparatively manageable investment and operating costs enables a fast return on investment ...

Technical specifications

| Laser power |

3 to 12 kW* |

| Minimum tube diameter |

12 mm* |

|

Maximum tube diameter |

510 mm* |

| Minimum dimension square profile | 12 x 12 mm* |

| Maximum dimension square profile | 510 x 510 mm* |

| Positioning accuracy | ±0.05 mm/m |

| Positioning repeatability | ±0.03 mm/m |

| Maximum weight per tube/profile | 1500 kg* |

| Maximum material length loading | 12000 mm* |

| *depending on the specific configuration of the series | |

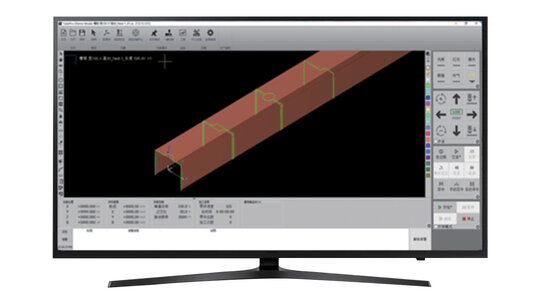

Software

The TubePro® software from Bochu is characterized by the following features, among others:

- Intuitive step-by-step support for machine operators

- CAD/CAM software for nesting is integrated

- Fast height adjustment for very high and consistent cutting quality

- Integrated monitoring of peripheral devices such as laser sources and sensors

Control

Bochu FSCUT5000® machine control

Operation via a dual panel

Thanks to high-quality components and a clever machine design, the MSE TubeFL simplifies many processes in laser tube cutting. The FSCUT5000® from Bochu – a highly precise, ultra-fast and extremely innovative EtherCAT CNC control system – ensures the best performance of the overall system. It was specially developed for fiber laser tube cutting machines. The highly agile system enables high-performance control of several chucks and a 3D bevel unit for the realization of weld seam preparations.

In combination with the user-friendly and highly functional TubePro® software, users work with one of the most advanced and user-friendly solutions for tube and profile processing.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

MSE SmartFL

MSE SmartFL

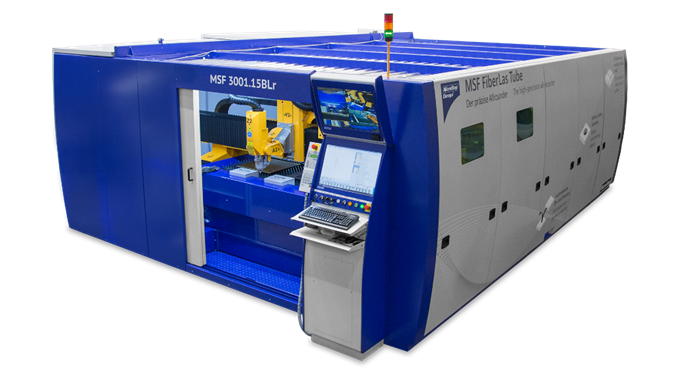

MSE TubeFL

MSE TubeFL

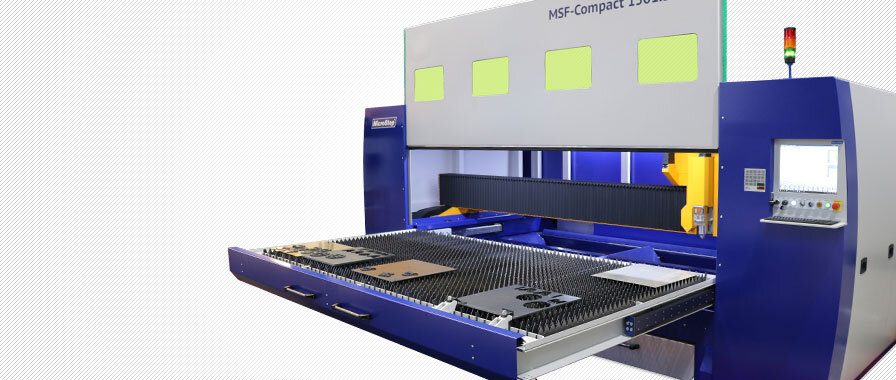

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

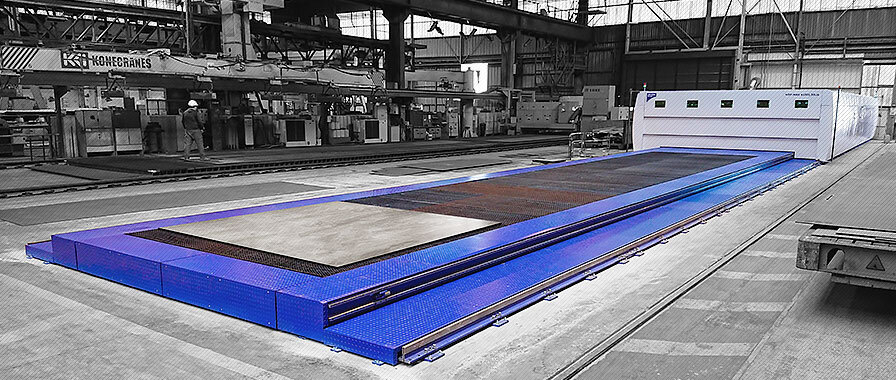

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

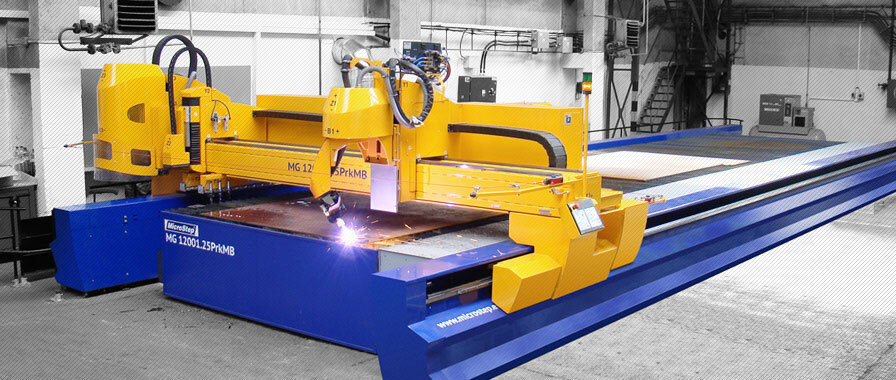

MG

MG

DRM

DRM

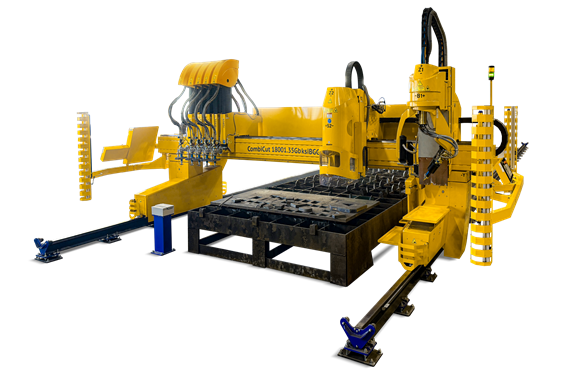

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

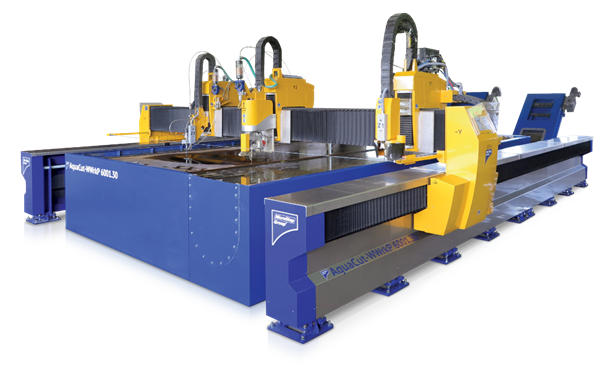

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization