With the right philosophy, waterjet cutting is not only effective and precise, but also extremely ecological

Waterjet cutting: green technology with many advantages

For waterjet cutting systems, MicroStep relies on the interaction of modern and environment-friendly solutions

Published 06.04.2022 | Erich Wörishofer

Ecological and sustainable aspects are also playing an increasingly important role in industry. There are enormous differences here, for example, in the machinery. When it comes to the appropriate solution for cutting, waterjet cutting is considered one of the most environmentally friendly cutting technologies on the market. No toxic fumes are produced, no gas is added. Extraction and filtering of the air is not required. However, in order to properly evaluate the aspect of environmental friendliness, prospective customers for a waterjet cutting machine should include the entire recycable materials concept of their potential cutting technology supplier.

Environmental protection begins with the construction of the machine. MicroStep traditionally manufactures all machines according to strict guidelines that apply nationally at the production sites in Slovakia and are also subject to European environmental directives. In addition to environment-friendly production, eco-friendly design is also an important part of the MicroStep philosophy.

Waterjet cutting machines from MicroStep have encapsulated drive systems that safely prevent the leakage of lubricants. The motors used are optimized for the greatest possible efficiency and, for the cutting heads, attention is paid to the possibility of being able to separately replace the wearing parts such as nozzles and mixing chamber and to continue to use the cutting head. If required, it is even possible to use zinc-free carrier plates for the workpiece support.

The ultra-high pressure pumps used by MicroStep are also extremely environment-friendly. With direct-drive pumps, the cooling water is no longer completely or at least partially discharged down the drain, as was the case in the past; with state-of-the-art solutions, it is first used for cooling, then pumped into a closed container, and finally used completely for cutting. This can significantly reduce the water consumption.

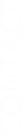

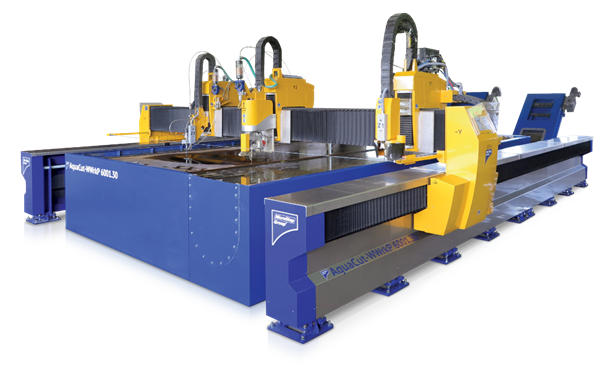

The AquaCut series cutting system stands for high-precision waterjet cutting and, of course, for 3D processing without thermal effects. Thanks to modern, well conceived technology and strong partners, waterjet cutting machines from MicroStep are also good for the environment. This configuration with rotator can be experienced at the MicroStep CompetenceCenter North in Dorsten (Germany, North Rhine-Westphalia).

Manufacturers have also made great progress in recent years when it comes to oil consumption and oil-related environmental safety. Modern booster pumps, for example, operate with extremely small quantities of hydraulic oil and fast, efficient drive motors. Leakage holes, which were previously used for visual inspection, are now scanned with sensors and the leaking medium is collected in closed containers. In the event of a leak, the entire oil content of the pumps used by MicroStep is absorbed by integrated sumps and thus cannot end up in the environment. Even in water protection areas, additional sumps are therefore no longer required. A major advantage compared to outdated waterjet cutting systems.

Other important aspects: Water, wastewater, additives and waste disposal

When it comes to the environmental compatibility of waterjet cutting technology, it is not only the CNC machine that needs to be considered; another important aspect concerns the consumables: the water must meet certain criteria in terms of its composition. In addition to the pH value and the degree of hardness, other different criteria are checked. If the water does not sufficiently meet these requirements, it must be treated. There are various ways to do this, using filters or additives to meet the manufacturer's specifications. During a MicroStep technology consultation, the experts objectively look at the production processes and the products to be manufactured, point out optimization potential, work out suggestions for improvement, and plan the path to modern production in detail with the customer. In the course of this independent and precise consultation, the water quality is also checked and, if necessary, treatment to meet the customer's requirements is taken into account and offered. The additive recommended by MicroStep is environment-friendly and does not contain any substances subject to identification. It is harmless for discharge into wastewater and is not subject to GHS labeling requirements.

Cutting with waterjet has several advantages over other cutting methods. These include the natural ecological aspect. But if manufacturers want to produce the most innovative and environmentally compatible systems possible, the entire cycle must work together. From the design and the use of suitable components to the use and disposal of water and abrasive sand.

Natural products for optimal results

The abrasive sand, like the water, is a natural product. The sand is offered on the market in different qualities and grain sizes. MicroStep cooperates with the partner GMA Garnet. The experienced and worldwide leading supplier of industrial garnet sand delivers high quality products and also takes care of the recycling of the associated cutting waste. Sand as well as water are pure natural products and in the form used absolutely uncritical for the environment.

When it comes to the environmental compatibility of the waterjet cutting process, however, there is a third component to consider: the "notch material". In other words, the material that is ground out of the sheet, i.e. the flat material to be cut, during the cutting process. The volume of the notch material can be roughly calculated by multiplying the cutting width by the cutting length and the material thickness. The percentage of notch material in the total waste varies with speed, material type and thickness, and the amount of sand used. For example, the percentage of notch material ranges from 0.3 vol, % when cutting 5 mm thick aluminum to 6 vol, % when cutting 50 mm thick steel. This notch material, which the operator of a waterjet cutting machine must dispose of as waste along with his used abrasive sand, should ideally be recycled. Here, too, MicroStep partner GMA Garnet supports the customers.

To keep freight costs low and avoid empty runs, GMA Garnet not only delivers the required abrasive sand, but also takes back the previously produced sludge in the course of this delivery. The sludge is later analyzed and checked for any contaminants. Provided one cuts the usual materials such as stone, aluminum, steel, etc., the sludge is usually recyclable. The analysis is valid for five years. If the sludge is contaminated – for example by heavy metals – then the waste is sent to an appropriate landfill according to its respective classification. The analyses required for this are repeated annually.

Protecting the environment with MicroStep systems

During recycling, the notch material is separated from the sand and returned to the metal cycle. The sand is largely reprocessed and returns to the market in the form of abrasive sand of smaller grain sizes. The components that can no longer be recycled go into road construction as fill material or are used in other sensible and environmentally friendly ways.

In any case, the customer receives a disposal certificate for his consumables and the certainty that his MicroStep waterjet cutting machine is actively protecting the environment.

"When considering waterjet cutting technology for environmental sustainability, interested parties need to shed light on several aspects and the entire cycle of components involved. This is where there has been tremendous progress in the industry over the past few years. With waterjet cutting systems from MicroStep, several gears mesh – from the construction to the disposal of the abrasive – to meet the high standards of the cutting process in terms of precision and reliability, but also in terms of ecology and sustainability."

Heinz Eichhorn,

Sales Manager Waterjet Technology | MicroStep Europa GmbH

Exemplary fields of application for waterjet cutting systems

- Pre- and finished products for steel construction

- Machine components in the tenths tolerance range

- Sheets of all qualities and thicknesses up to 150 mm

- Prototype components

- Small and medium series

- Shipbuilding

- Mechanical engineering

- Plant construction

- Crane components

- Vehicle components

- Tensile specimens

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

MSE SmartFL

MSE SmartFL

MSE CubeFL

MSE CubeFL

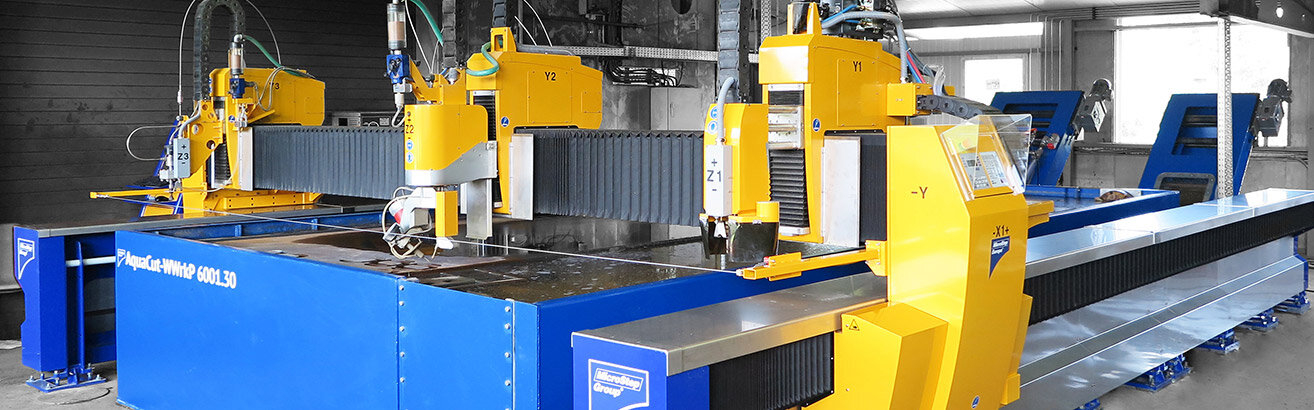

MSE TubeFL

MSE TubeFL

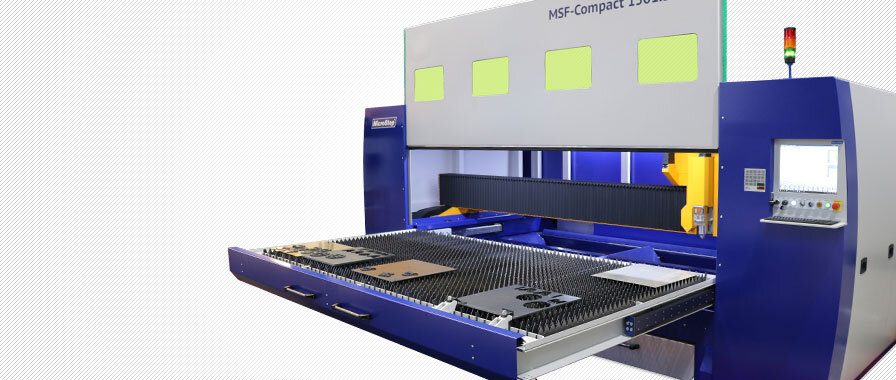

MSF Compact

MSF Compact

MSF Cut

MSF Cut

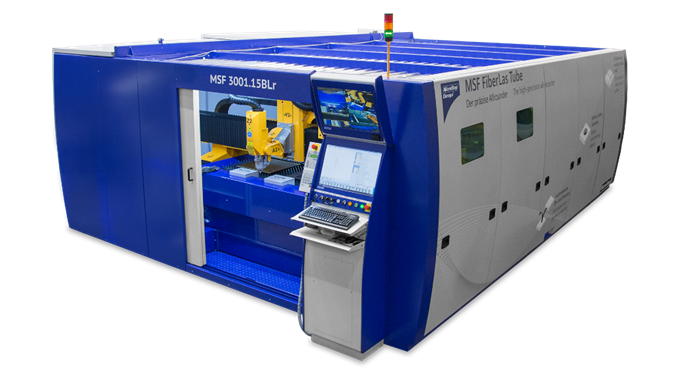

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

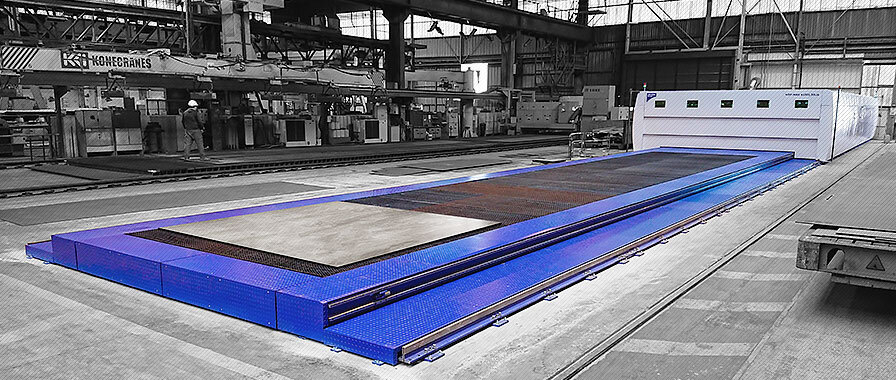

MasterCut

MasterCut

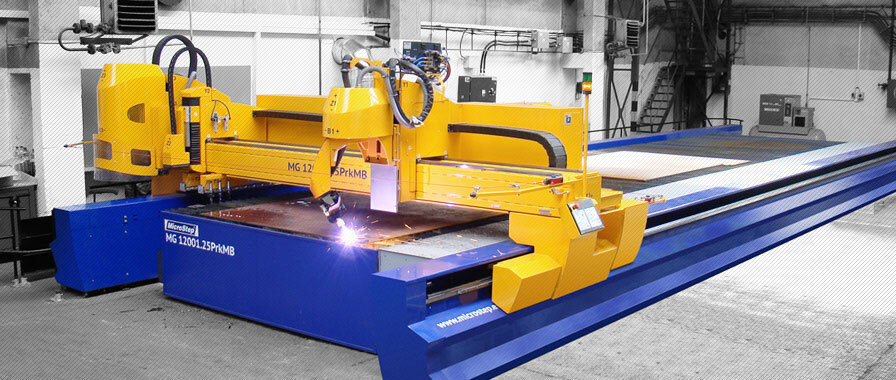

MG

MG

DRM

DRM

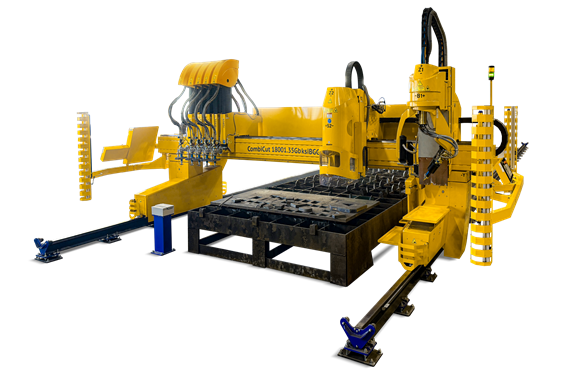

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

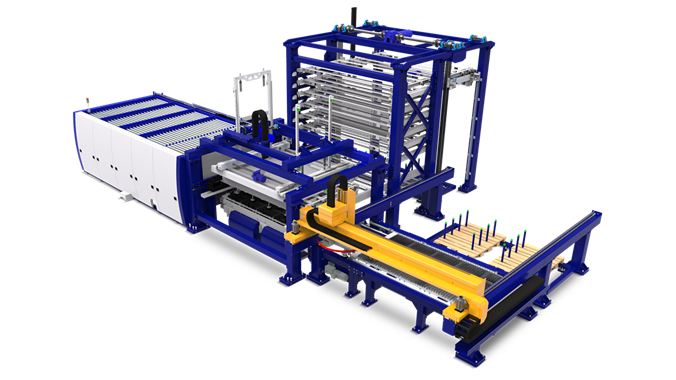

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization