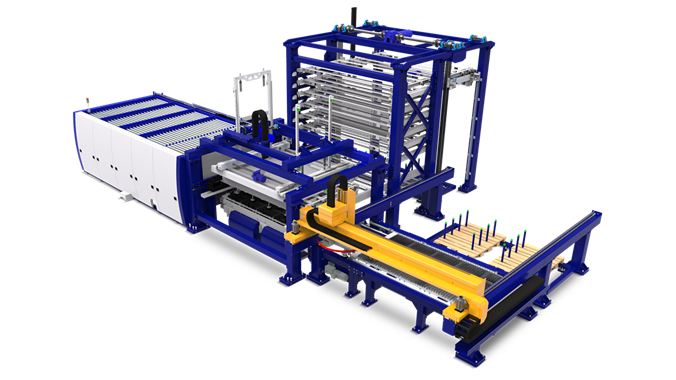

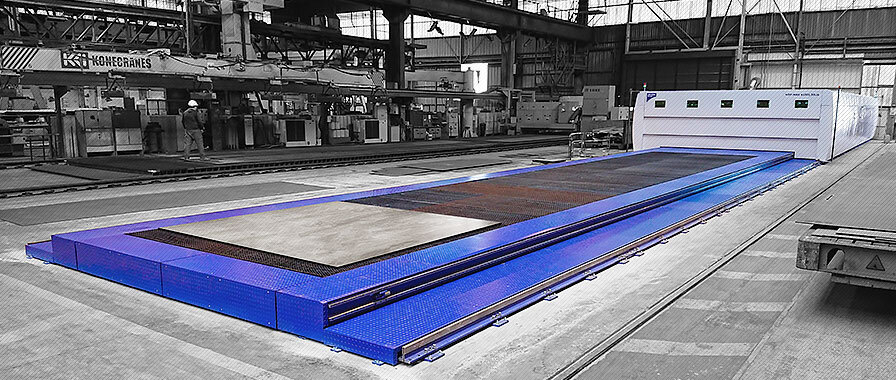

MSLoop: a shuttle table system moving in a paternoster system for even greater efficiency

Australian shipyard invests in highly efficient solution

MicroSteps shuttle table system MSLoop is part of the innovative technology park at Osbourne Naval Shipyard, a project initiated by the Australian government to create state-of-the-art domestic production facilities

Published 07.10.2020 | Erich Wörishofer

Company profile:

Osborne, SA 5017

Australia

Australian Naval Infrastructure Pty Ltd (ANI) is an Australian Government commitment to establish a state-of-the-art infrastructure for the domestic production of world-class naval vessels. The aim is to create outstanding opportunities for naval shipbuilding with innovative systems throughout the technology park in southern Australia. The project includes the Osbourne Naval Shipyard.

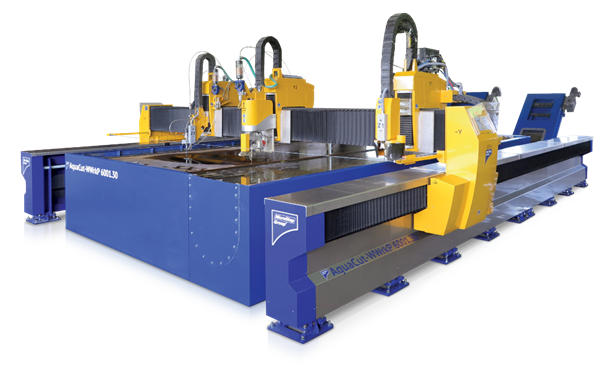

Australian Naval Infrastructure Pty Ltd (ANI) chose the MicroStep MSLoop system in search of advanced technology. The intelligent shuttle table solution allows simultaneous loading, cutting and unloading of large format plates with different processing options.

Machine profile:

MSLoop- Shuttle table system consisting of several cutting grids moving in paternoster principle for simultaneous loading, cutting and unloading

- 3x working area 13,000 x 3,500 mm

1. Gantry: DRM series

- Sand blasting unit for primer removal + Plasma marking

- Inkjet marking

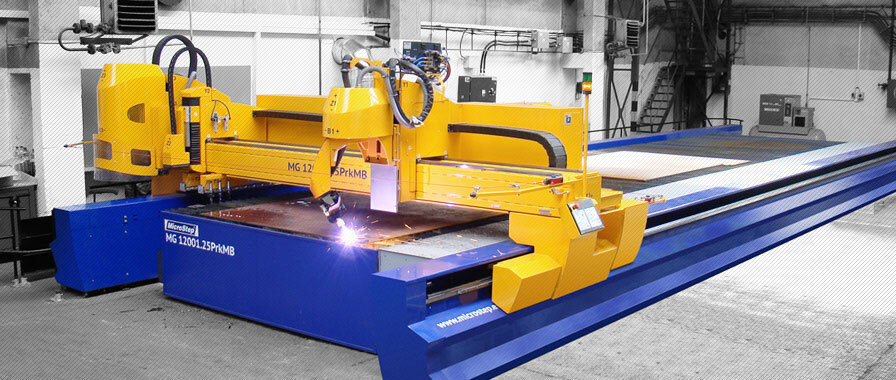

2. Gantry: MG series

- Plasma rotator for weld preparation up to 52° with auto-calibration feature (ACTG®)

MG series

- Working area 13,000 x 3,500 mm

- Oxyfuel rotator for weld preparation up to 65° with auto-calibration feature (ACTG®)

The development and production of solutions for shipyards are complex and demanding. The highest standards are applied to engineering, precision and stability with extraordinary processing sizes. Part of a special project is MicroSteps MSLoop. The new shuttle table system is part of the innovative technology park of the Osbourne Naval Shipyard in Adelaide, Australia, a project of the Australian government to create state-of-the-art infrastructure for the domestic production of world-class naval ships. The name of the project: Australian Naval Infrastructure Pty Ltd (ANI).

MSLoop is a brand new solution in MicroStep's portfolio. The intelligent shuttle table system allows simultaneous loading, processing and unloading of large format plates. The system can be equipped with several gantries on which a wide range of processing technologies can be integrated. From the plasma rotator, to the marking tool, to the sandblasting system. The technical principle behind the solution is based on a paternoster: three shuttle tables rotate in a continuous loop from one zone to the next: from the loading zone to the processing zone and, after cutting, to the unloading zone – after complete unloading, the table then moves under the cutting system back to the starting point. This makes MSLoop another versatile MicroStep solution that can be configured for many different tasks.

The Australian shipyard decided on a version with two gantries. One gantry is equipped with a plasma rotator for weld edge preparation up to 52°, the second gantry is equipped with a sandblasting unit for removing primer and an inkjet marker.

The installation of the MSLoop in the Australian shipyard was completed in spring 2020. Preparations are currently in full swing for the start of production at the high-tech shipyard. The MSLoop is also currently being optimized and calibrated for full production. Phil Cornish, Project Manager at Australian Naval Infrastructure, praised the successful commissioning on the LinkedIn online portal: "A great commitment by our partners to make this project a success".

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

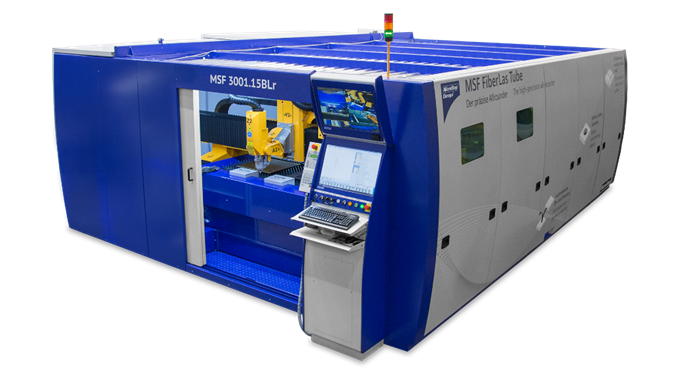

MSE SmartFL

MSE SmartFL

MSE CubeFL

MSE CubeFL

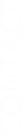

MSE TubeFL

MSE TubeFL

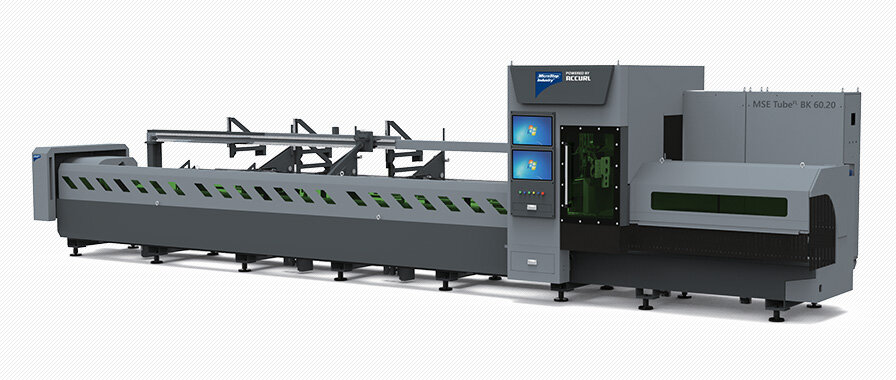

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

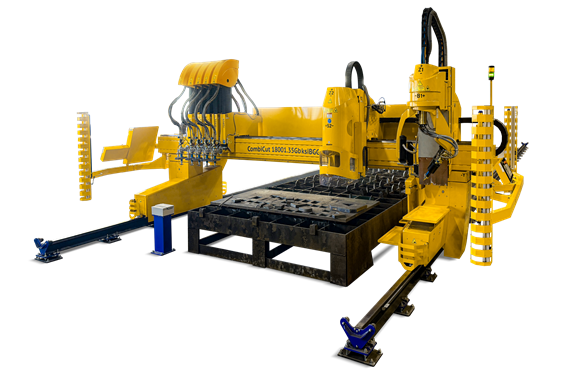

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization