Meyer Turku Oy benefits from flexible systems at various locations

Leading shipbuilder relies on special and flexible systems from MicroStep

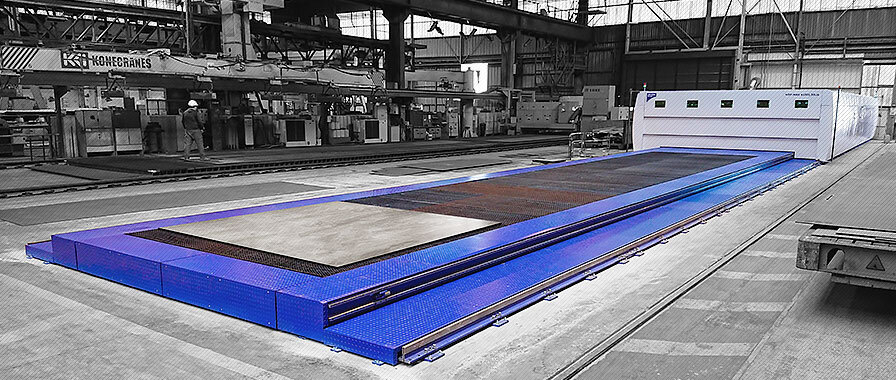

Meyer Turku uses a plasma cutting system including a water cutting table with variable water level and a working area of 50,000 x 8,000 mm

Published 07.11.2016 | Erich Wörishofer

Company profile:

Meyer Turku Oy is one of the leading European shipbuilding companies. Meyer Turku (formerly STX Finland) is specialized in the construction of cruise ships, car passenger ferries and special ships. Over the years the shipyard has built more than 1,300 new ships for customers all over the world.

Machine profile

DRM series- Working area 50,000 x 8,000 mm (underwater cutting)

- Plasma rotator for weld preparation up to 50° with auto-calibration feature (ACTG®)

- Inkjet marking

- Operator platform with MMI console on the gantry

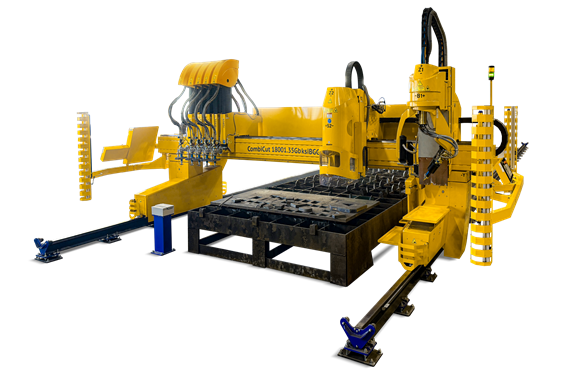

2x CombiCut series

- Working area 12,000 x 3,500 mm

- 2x Plasma rotator in parallel operation for weld preparation up to 50° + auto-calibration feature (ACTG®)

- Plasma marking

- Inkjet marking

- Automatic plate edge detection

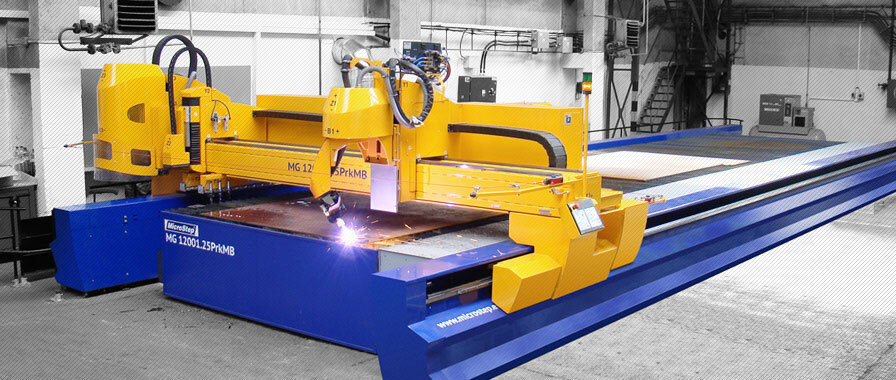

2x DRM-PL series

- Working area 12,000 x 3,500 mm

- Plasma rotator for wled preparation up to 50° with auto-calibration feature (ACTG®)

- Inkjet marking

- Sand blasting unit for primer removal + plasma marking

- Automatic plate edge detection

Meyer Turku Oy owns three shipyards in Finland:

The Turku shipyard builds cruise ships and other technically demanding special ships as well as offshore plants.

The shipyard in Rauma is known for the production of ferries, research vessels, naval ships and multipurpose freighters.

And the Arctech shipyard in Helsinki has specialized in the production of ice-breaking and ice-going offshore and polar ships.

The shipbuilding company, which has around 2000 employees, has been part of the German Meyer Werft since 2014.

The DRM 50001.80IPrk plasma cutting system with a water cutting table with variable water level has a working area of 50,000 x 8,000 mm.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

MSE SmartFL

MSE SmartFL

MSE CubeFL

MSE CubeFL

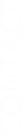

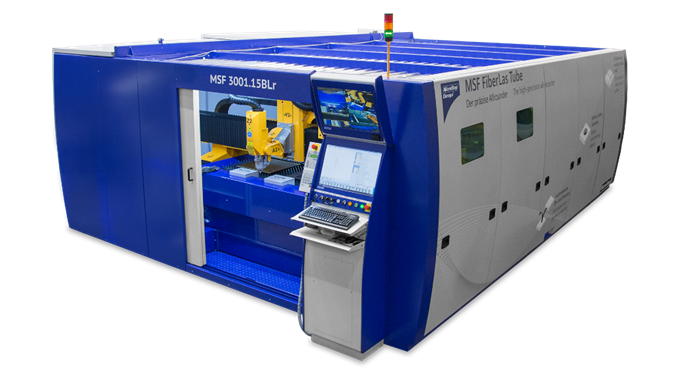

MSE TubeFL

MSE TubeFL

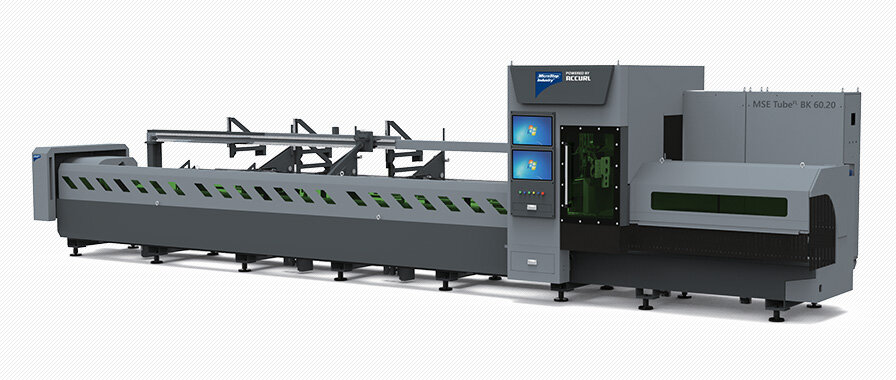

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

MG

MG

DRM

DRM

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

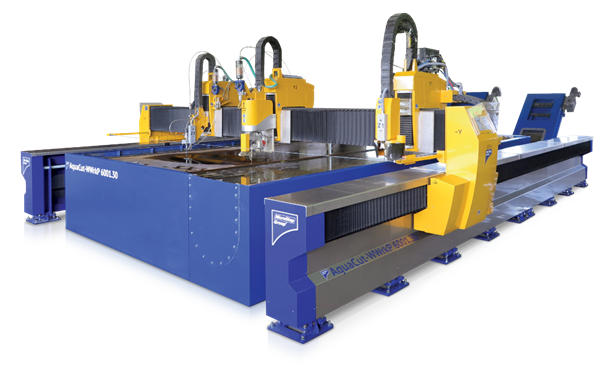

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

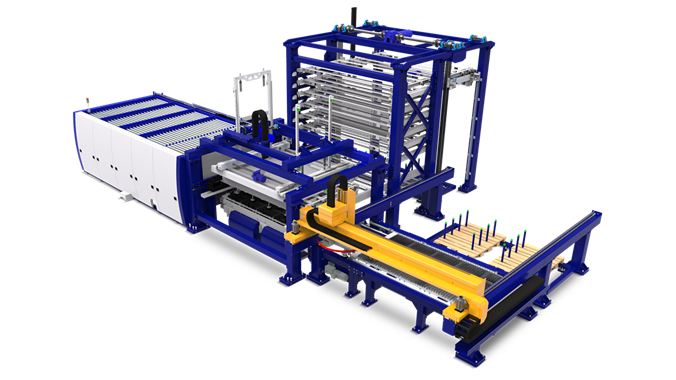

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization