The MSF Compact at Metallbau Pfister in Switzerland

"This is exactly the system we need, the precision is very impressive!"

Metallbau Pfister AG saves money and increases productivity with the fiber laser cutting system MSF Compact. At the production start, the investment is an important helper in a showcase project.

Published 17.06.2020 | Erich Wörishofer

Company profile:

San Bastiaun 57

7503 Samedan

Switzerland

The Swiss Metallbau Pfister AG, a traditional company with a long history of handicraft, offers a wide range of customers from various industries products in the fields of metal construction and locksmith work such as windows, conservatories, metal facades, stairs, sun protection, gates, solar systems, etc.

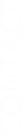

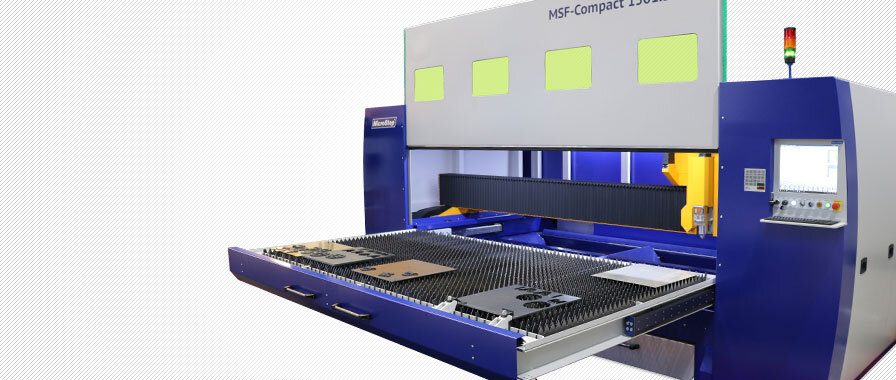

The Swiss company Metallbau Pfister AG invested in a version of the MSF Compact with a working area of 1,500 x 3,000 mm. The CNC machine, designed as an island solution, saves space in production and, thanks to a 6 kW laser source and EX-TRABEAM® PRO laser cutting head, offers quickly repeatable and highly precise results.

Too many bought-in expensive laser parts, a plasma cutting system that does not sufficiently cover the tasks at hand: the versatile Metallbau Pfister AG was looking for a compact laser cutting system that requires little space and promises high precision and speed. After good experiences with MicroStep, they found it in the MSF Compact. "The laser system runs like clockwork. This is the perfect machine for our space conditions," says Managing Director Curdin Pfister after several months in operation.

The Swiss Engadine: Metallbau Pfister AG is located just a few minutes' drive from the luxurious vacation resort of St. Moritz. A wide range of customers from various industries rely on the company's expertise and quality. "We are very flexible and broadly based. With us, customers often only come to the office with an idea. We try to fulfill the wishes of our customers with our expertise," says Managing Director Curdin Pfister.

The range of services is extensive – the projects, buildings and products in the fields of metal construction and locksmith work are correspondingly diverse. The AG, which has more than 30 employees, also offers engineering services and wrought-iron work.

The current showcase project is the production of the facade of the new Porta Samedan shopping center, just a few minutes' walk from the company's headquarters. The outer skin is formed by a 3 millimeter thin aluminum sheet, each single sheet is individually and precisely cut with a fiber laser cutting machine of the latest generation. The overall view of the perforated pattern results in a wave pattern that refers to the water-rich area and changes its appearance depending on the exposure to light.

Powerful fiber laser currently in use ten hours a day

The MSF Compact from MicroStep is used for this. The compact 2D system with a working area of 3,000 x 1,500 mm has been in operation since the end of 2019 and is in use ten hours a day. "The laser system runs like clockwork, which is very, very gratifying. This is the perfect machine for our space conditions," says Curdin Pfister. 80 percent of the fiber laser cutting system is currently running for the façade project. 3 mm anodized aluminum is processed, otherwise it is mainly connecting plates for beams cut from plate steel in thicknesses of 8, 10 and 12 mm. Thanks to the powerful 6 kW fiber laser source, sheets up to 20 mm can be cut.

No more buying expensive laser parts

For a new acquisition of the laser cutting machine it was decided, after having examined the expenditures for the laser contract cutter. These increased constantly. The in-house plasma cutting system – also from MicroStep – could no longer meet the changing and growing requirements. "We were satisfied, it worked out well. But it was no longer suitable for our requirements. We wanted a new machine that would meet our current requirements in terms of precision and speed". After Pfister had had good experiences with MicroStep, Curdin and his father Urs took a close look at the subject of fiber lasers. The plasma cutting system had to be sold due to lack of space, and a larger CNC cutting system with laser technology and shuttle table was also not an option. A visit to the MicroStep CompetenceCenter South and a live demonstration on the MSF Compact were the deciding factors. "It was very nice for us to drive to Bad Wörishofen and take a look at the system. We were able to cut our samples live, which further increased confidence in the system". It is now hardly necessary to purchase any additional parts.

"This is exactly the equipment we need for our work here at the company. It is small and compact and fits exactly into our limited space. The precision is very impressive."

Urs Pfister,

Managing Director | Metallbau Pfister AG

Machine profile:

MSF Compact series- Working area 1,500 x 3,000 mm

- 2D fiber laser – 6 kw

- Manually extractable shuttle table

Easy switch from plasma to laser technology from MicroStep

The change from MicroStep's plasma to the new fiber laser cutting system also went smoothly: "We were able to take a lot of knowledge with us, but also learned a lot from the technicians during the installation and asked many questions. That helped us to be flexible now".

For Curdin and his father Urs Pfister, the purchase paid off immediately. "This is exactly the equipment we need here in the company for our work. It is small and compact and fits exactly into our limited space. The precision is very impressive," says Urs Pfister, who is also a Managing Director.

OVERVIEW OF THE HIGHLIGHTS OF THE LASER CUTTING SYSTEM MSF COMPACT:

Space-saving and highly precise fiber laser with a processing area of 1,500 x 3,000 mm

The MSF Compact stands for precision and compact design. The fiber laser cutting system is quickly ready for operation: installation, commissioning and training are completed within just one week. Metallbau Pfister AG relies on a version with a processing area of 1,500 x 3,000 mm. The pull-out cutting table allows uncomplicated and fast loading and unloading. For the Swiss metal construction company, this is an ideal cutting system for 2D processing of different materials. "This is the perfect machine for our space conditions. The precision is very impressive," says Managing Director Curdin Pfister.

2D fiber laser cutting system with a 6 kW laser source

In addition to the compact design in the limited hall, the cutting quality and speed were decisive factors in the choice of the MSF Compact. As laser source, the metal construction company relies on an IPG fiber laser source of the type YLS 6000 CUT with 6 kW beam power for exact results in the thin and medium sheet thickness range. The compact laser is available with laser sources from 1 to 4 kW as standard. At the request of Pfister, the MSF Compact was designed for 6 kW. The Thermacut model EX-TRABEAM® PRO is integrated as laser cutting head. A low-drift control ensures the best cutting results, while the "Smart Protection" seal monitoring system protects the optical components.

EXPERIENCE OUR SYSTEMS LIVE

in the CompetenceCenter South or North

- All four cutting technologies (laser, plasma, oxyfuel, waterjet)

- Innovative automation systems

- The latest solutions for bending and deburring

- Industry 4.0 demo factory

- Easy to reach: in the south and north of Germany

MSE SmartFL

MSE SmartFL

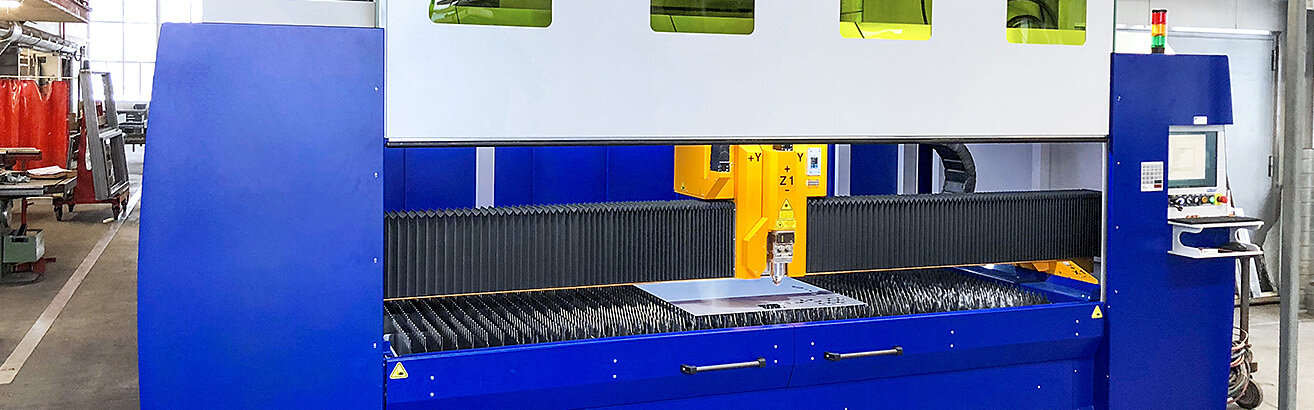

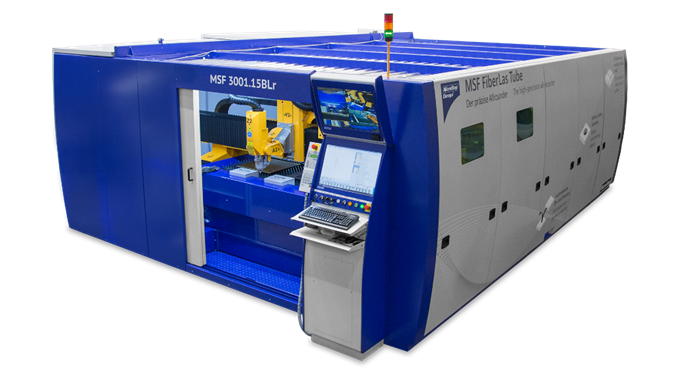

MSE TubeFL

MSE TubeFL

MSF Compact

MSF Compact

MSF Cut

MSF Cut

MSF Pro

MSF Pro

MSF Max

MSF Max

MSF Pipe

MSF Pipe

MasterCut Compact

MasterCut Compact

MasterCut

MasterCut

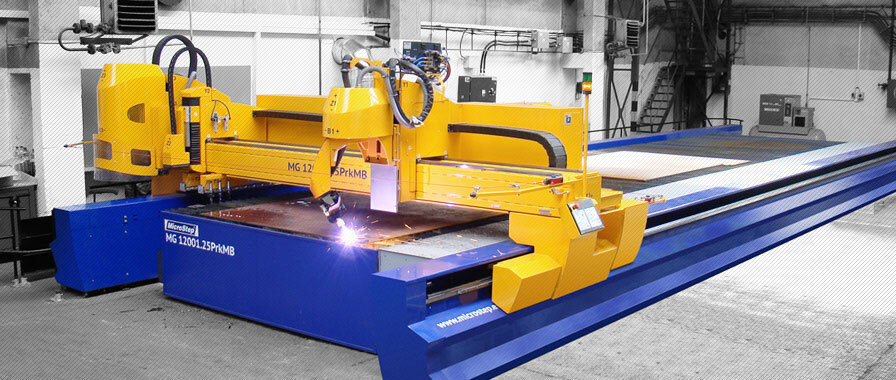

MG

MG

DRM

DRM

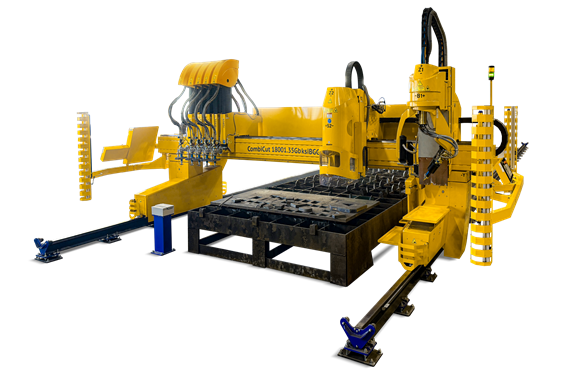

CombiCut

CombiCut

DS

DS

CPCut & PipeCut

CPCut & PipeCut

ProfileCut

ProfileCut

EasyCut

EasyCut

WaterCut

WaterCut

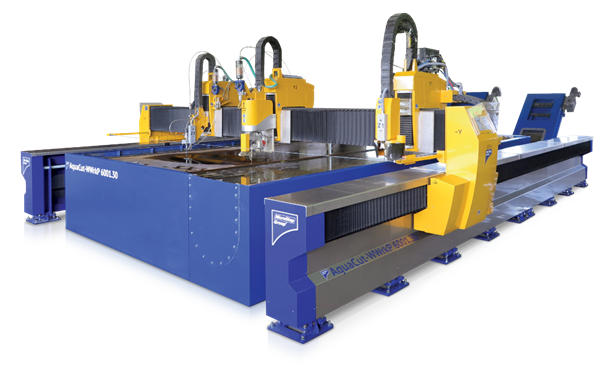

AquaCut

AquaCut

eB ULTRA

eB ULTRA

EUROMASTER

EUROMASTER

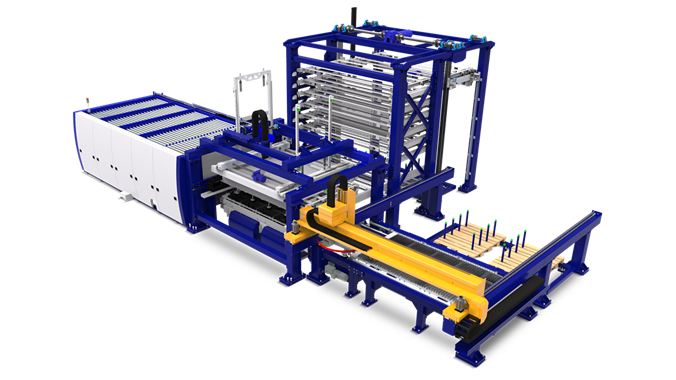

MSLoad, MSTower, MSSort

MSLoad, MSTower, MSSort

MSLoop

MSLoop

MSFeed

MSFeed

Digitalization

Digitalization